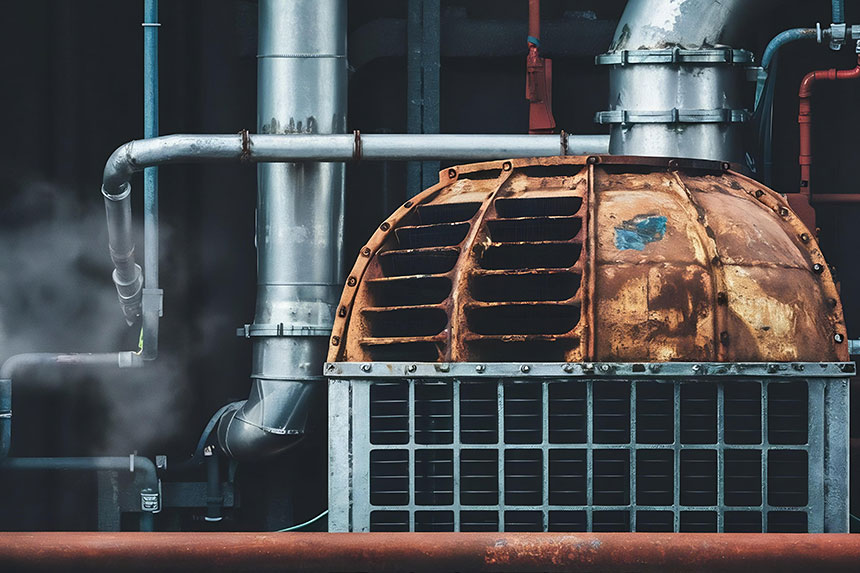

Starting and shutting down a cold boiler system might seem like a big task. But when done properly, it’s a routine process that keeps everything running the way it should. Whether you’re working with an industrial boiler or a residential system, understanding the right steps helps keep things safe, avoid damage, and prevent costly issues.

Let’s walk through the entire process, from the moment the boiler is cold to the moment it’s safely turned off again—all in simple, clear steps.

Safety First, Always

Safety sits at the heart of every start and every stop. Before any switch or valve, set the stage for safe work. Allow time, move slowly, and follow the manufacturer’s manual for your model. Wear gloves and eye protection, keep the area clear, and make sure a working carbon monoxide alarm is nearby. Small habits like these protect people, property, and the system itself.

Gather Simple Tools and Set the Space

Good prep keeps stress away and helps each step flow into the next.

- Clean rags and a flashlight

- A small bucket and a hand brush

- A basic wrench set and screwdriver

- Teflon tape for minor fitting touch-ups

- A reliable pressure gauge if yours is suspect

- Boiler manual and a pen for notes

Clear snow, leaves, and clutter. Confirm that fresh air can reach the burner. Check that floor drains or discharge lines stay open. Place tools within reach to avoid rushing later.

Quick Health Check Before a Cold Start

A cold start asks the metal, water, and burners to wake up in harmony. A few minutes of checks reduce wear and stop surprises.

- Look for stains, rust trails, or damp spots around joints and valves.

- Confirm the pressure relief valve discharge line is clear and aimed safely.

- Inspect the expansion tank for proper charge or correct water level.

- Verify that the system pressure and water level match the manual.

- Open isolation valves that should be open; keep service valves closed if the manual says so.

- Bleed air from high points if your system has manual vents.

- Make sure fuel supply valves are open and tight, with no smell of fuel.

- Confirm the circulator pumps spin freely; a gentle nudge with the power off can help if safe and allowed.

Step-by-Step: Starting a Cold Boiler

Move through each step with care. Slow and steady heat protects the boiler from stress.

1) Power and controls

Turn on the electrical power for the boiler and controls. Set the thermostat to call for heat. Watch the control panel lights. Listen for the circulator or draft fan as the sequence begins.

2) Purge or vent as required

If your manual calls for a purge, run it. Air trapped in the system causes noise, hot spots, and weak heat transfer. Bleed small amounts of air at radiators or high vents until steady water appears.

3) Confirm fuel supply

Open the main fuel valve if it is not already open. For gas, check flexible connectors and unions for tightness. For oil, confirm the tank has fuel and the filter looks clean. For wood or solid fuel units, set dry fuel aside and keep the loading area clean and dry.

4) Burner light-off

Allow the controls to handle ignition. Modern systems manage pre-purge, spark, and flame detection. Watch for a stable flame through the sight glass if your unit has one. If the flame fails, stop and follow the lockout reset steps in the manual rather than repeating starts.

5) Warm up slowly

As water temperature rises, keep an eye on the pressure gauge. The needle should climb in a smooth, steady way. Small corrections now prevent swings later. Adjust the thermostat in small steps so pipes and radiators heat evenly.

6) Check flow and distribution

Walk the loop. Feel supply and return lines with care. Warm supply and cooler return show flow. Uneven heat can mean air, a closed valve, or a stuck zone valve. Release air again if needed and confirm zone valves respond to their controls.

7) Verify relief and safeties

Watch for any weeping at the pressure relief valve. Confirm the low-water cut-off status if equipped. Safeties protect the system when conditions drift, so keep them in healthy shape.

8) Stabilize

Let the boiler reach its normal operating range. Once steady, note the temperature and pressure, the burner cycle time, and any small noises. Write these in a simple log. These notes help spot changes early in the season.

Keep It Smooth While Running

Even after a good start, the system likes gentle care. Dust the burner area. Wipe up small drips. Tighten loose screws on covers. Listen for new rattles or a whistling vent. Short daily checks keep small issues from growing. Because of this steady attention, the boiler works more easily, and fuel goes further.

Step-by-Step: Shutting Down to Cold

When the heating period ends, or when maintenance calls for it, bring the boiler down with patience. Heat leaves metals and water at different rates, so slow steps matter.

1) Lower the call for heat

Turn the thermostat down. Let the burner stop on its own. Keep the circulator running as controls allow so heat carries out of the block and into the system.

2) Let the unit cool

Give the boiler time to cool naturally. Rapid cooling stresses metal. With slow cooling, gaskets settle and seals stay happy.

3) Close the fuel supply

Close the manual fuel shutoff if your manual recommends it for seasonal layup. For solid fuel units, clear the firebox and ash pan only when fully cold. Store fuel in a dry, safe place away from the unit.

4) Power down with care

When the boiler is cool, turn off electrical power if the manual allows seasonal power-off. Some systems feed controls that protect pipes; follow the book for your setup.

5) Drain or protect, based on climate

In mild climates, leave the system filled and oxygen exposure low. In freezing regions, follow the manual for glycol concentration or controlled draining. Label valves and caps so the next start returns the system to its normal path.

6) Clean and cover

Brush soot only with the right tools for your boiler type. Vacuum dust. Wipe sensors and wire runs with a dry cloth. Replace any tired gaskets. A clean cabinet and flue area support an easier start next season.

Care During the Off-Season

A quiet boiler still needs small touch-ups. Cycle isolation valves once a month to keep them from sticking. Spin circulator impellers by hand if the design allows and the power is off. Check for condensation or nesting pests in vent paths. Keep the area dry and tidy. These small acts build confidence before the next cold start.

A Simple Log That Pays Off

A pocket log helps a lot. Note date, starting pressure, starting temperature, final steady readings, and any small adjustments. Add a line after each cleaning or part change. Over time, the log shows patterns, and those patterns guide quick fixes before comfort slips.

Final Thoughts

Cold starts and careful shutdowns shape the life of the boiler. Each gentle step protects metal, seals, pumps, and people. With steady habits, the system warms the building evenly, uses fuel wisely, and rests well in the off-season. For help with a cold boiler, Ariel Outdoor Boilers provides cold boiler service with care.fault, reach out to Ariel Outdoor Boilers.